I too have read all the pages on this forum and was about to buy a 16 ATS-V until I Read about the oil issue on both the blue coupe and white sedan. The problem still seems to be a mystery until they look at his old engine. But with that being said I’ve noticed that it’s not all 16 & early 17 model ATS-V’s that have this problem. So what it comes down to when buying a used one, like I intend on doing is seeing what kind of warranty I can get. Say if I get this oil problem will I get a new engine too??? If warranty won’t cover it then I might go with the M4... definitely 100% rather have the V!I have read this entire post and am wondering if you would suggest a ATS-V to a prospective buyer or advise them to steer clear? I am a prospective buyer. I am looking for a used sedan so as to let someone else eat the depreciation.

My background is this: I am a 50 yr old car guy who gravitates toward "sleepers". I had a 2011 Subaru WRX STI hatchback which was pro tuned and I upgraded most of the suspension components. I loved that car but it was a little rough around the edges and wasn't a lot of fun in heavy traffic. When it showed signs of potential engine trouble on the horizon, I decided to trade it in and get something more comfortable and yet still practical. I opted for a 2016 Ford Edge Sport. I immediately realized I had gone too soft and started looking for a track car or weekend car. I purchased a 2011 Corvette Grand Sport with 14k miles and upgraded the brake fluid and pads. Amazing track car! but I just didn't drive it enough. I just sold that car and am now searching for a really fun daily driver (I will trade or sell the Edge Sport) that is sufficiently comfortable.

I am not particularly tied to any particular brand but I do want four doors and a hatch or decent trunk with folding rear seats. I will probably buy a very low mileage used car, preferably a one owner personal lease vehicle. I would like to spend in the $35-45k range.I am not looking for 0-60 times but a car with great suspension that feels like a drivers car in the twisty roads I am considering a ATS V, Genesis G70 3.3T Sport, Alfa Romeo Guilia Ti Sport, VW Golf R (which I would modify immediately to reach my performance goals) or a Chevy SS. While there are many other from the German stable which interest me, I don't want to drive the same brand as many of the more snobby/obnoxious people around me tend to drive. I am undecided. I was just about to pull the trigger on 10k mile 2016 ATS V which was loaded with every option. I went so far as to have a 3rd party mechanic inspect the car for me. After reading your experiences, I hit the brakes.

Honest opinion? Would you suggest a 2018 or should I scratch it off my list? This will be my only vehicle. I want some degree of reliability. I don't mind replacing a touch screen panel and would probably add a downpipe and spark plugs when tuning the car. Transmission problems or turbo seal leakage and cylinder or head damage is a different story. While I am a adult capable of making his own decisions, I would greatly appreciate any advice you might have. Thank you in advance for your consideration

Welcome to the Cadillac V-Series Forums!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A Little-V Blog: The ATS-V purchase and ownership experience

- Thread starter Hib Halverson

- Start date

CTspeedFReaK

New Member

The more I think about it, the less comfortable I am trusting that GM/Cadillac will give the customer a honest and fair response if problems occur. There were problems with Corvettes too but it was higher volume car so there was a aftermarket which filled the void left by GM and their parts suppliers. I don't expect a car not to have failures. I just want to know that some sort of a fix is possible. Receiving a replacement part that is just as likely to fail is a deal breaker for me. It is very frustrating to find a car with such potential for greatness let down by some poorly designed parts and a inability to remedy the problem.

Hib Halverson

Technical Writer for Internet & Print Media

- Joined

- Mar 20, 2015

- Messages

- 229

- Location

- CenCoast CA

- V-Series Cadillac(s)?

- 2016 ATS-V Sedan, 2016 ATS-V Coupe

So far, I've been unable to ascertain what the problem is with LF4 engines built in 2016 which causes only the front two cylinders to have a loss of proper ring seal which causes the oil smoke on cold start problem.

There was some communication with my pal at Bunnin Cadillac, Technician Luis Rios, with a "Brand Quality Manager" at GM which indicated there was some kind of "materials problem" with the liners in those blocks, but that raises this question: if there was a "materials problem" how can it affect only liners used in #1 and #2? I'd think a materials problem could affect all the liners.

Beyond that communication between Rios and a BQM, I can only speculate. I don't know if the LF4 block is manufactured with wet or dry liners. If they're dry liners and their installation leaves voids or other problems between the block's bores and the liner, that could cause problems with ring seal. Once the liners are installed and machined, if the front of the block distorts when the front cover fasteners are tightened, that could cause a ring seal problem, too. The only conclusion I can make at this point is that once, we misdiagnosed the cause as faulty valve stem seals and twice we misdiagnosed the problem as failed turbocharger shaft seals. Also, the early concern with engine oil was a dead end. Engine oil choice never played a part in the oil smoke on cold start problem.

At one time I had a good contact with the GM Communications Manager for the now defunct GM Global Propulsion Systems, however, GPS was disbanded and its Communications Manager's job was eliminated. I'm attempting to make contact with whomever at GM Communciations deals with Cadillac engineering in hopes of getting more information about this engine problem.

There was some communication with my pal at Bunnin Cadillac, Technician Luis Rios, with a "Brand Quality Manager" at GM which indicated there was some kind of "materials problem" with the liners in those blocks, but that raises this question: if there was a "materials problem" how can it affect only liners used in #1 and #2? I'd think a materials problem could affect all the liners.

Beyond that communication between Rios and a BQM, I can only speculate. I don't know if the LF4 block is manufactured with wet or dry liners. If they're dry liners and their installation leaves voids or other problems between the block's bores and the liner, that could cause problems with ring seal. Once the liners are installed and machined, if the front of the block distorts when the front cover fasteners are tightened, that could cause a ring seal problem, too. The only conclusion I can make at this point is that once, we misdiagnosed the cause as faulty valve stem seals and twice we misdiagnosed the problem as failed turbocharger shaft seals. Also, the early concern with engine oil was a dead end. Engine oil choice never played a part in the oil smoke on cold start problem.

At one time I had a good contact with the GM Communications Manager for the now defunct GM Global Propulsion Systems, however, GPS was disbanded and its Communications Manager's job was eliminated. I'm attempting to make contact with whomever at GM Communciations deals with Cadillac engineering in hopes of getting more information about this engine problem.

Last edited:

Hib Halverson

Technical Writer for Internet & Print Media

- Joined

- Mar 20, 2015

- Messages

- 229

- Location

- CenCoast CA

- V-Series Cadillac(s)?

- 2016 ATS-V Sedan, 2016 ATS-V Coupe

I have read this entire post and am wondering if you would suggest a ATS-V to a prospective buyer or advise them to steer clear? I am a prospective buyer. I am looking for a used sedan so as to let someone else eat the depreciation.

My background is this: I am a 50 yr old car guy who gravitates toward "sleepers". I had a 2011 Subaru WRX STI hatchback which was pro tuned and I upgraded most of the suspension components. I loved that car but it was a little rough around the edges and wasn't a lot of fun in heavy traffic. When it showed signs of potential engine trouble on the horizon, I decided to trade it in and get something more comfortable and yet still practical. I opted for a 2016 Ford Edge Sport. I immediately realized I had gone too soft and started looking for a track car or weekend car. I purchased a 2011 Corvette Grand Sport with 14k miles and upgraded the brake fluid and pads. Amazing track car! but I just didn't drive it enough. I just sold that car and am now searching for a really fun daily driver (I will trade or sell the Edge Sport) that is sufficiently comfortable.

I am not particularly tied to any particular brand but I do want four doors and a hatch or decent trunk with folding rear seats. I will probably buy a very low mileage used car, preferably a one owner personal lease vehicle. I would like to spend in the $35-45k range.I am not looking for 0-60 times but a car with great suspension that feels like a drivers car in the twisty roads I am considering a ATS V, Genesis G70 3.3T Sport, Alfa Romeo Guilia Ti Sport, VW Golf R (which I would modify immediately to reach my performance goals) or a Chevy SS. While there are many other from the German stable which interest me, I don't want to drive the same brand as many of the more snobby/obnoxious people around me tend to drive. I am undecided. I was just about to pull the trigger on 10k mile 2016 ATS V which was loaded with every option. I went so far as to have a 3rd party mechanic inspect the car for me. After reading your experiences, I hit the brakes.

Honest opinion? Would you suggest a 2018 or should I scratch it off my list? This will be my only vehicle. I want some degree of reliability. I don't mind replacing a touch screen panel and would probably add a downpipe and spark plugs when tuning the car. Transmission problems or turbo seal leakage and cylinder or head damage is a different story. While I am a adult capable of making his own decisions, I would greatly appreciate any advice you might have. Thank you in advance for your consideration

The cars you list are a pretty wide range, however, if you are really focused on the compact sedan segment, of the cars you list, the ATS-V and Guilia are characteristic of cars that size. If you are concerned about performance, keep in mind that the ATS-V is a much better choice than the Giulia Ti Sport. The only Alfa that compares to the ATS-V is the Giulia Quadrifoglio. Both can be had as four-door sedans. I'd say their quality and durability are comparable, ie: both can have problems. Both have great chassis. Both have lots of power with the edge going to the Quadrifoglio by about 40. With braking, the advantage goes to the Alfa but only if you buy the optional CCM brakes at $8000. If you decide on the ordinary iron brake rotors, both have equal braking abilities. There is no manual available in the Alfa.

If you're partial to the Cadillac, look for a low mileage '17 or '18. There were not ATS-V four-doors in 2019.

Hib Halverson

Technical Writer for Internet & Print Media

- Joined

- Mar 20, 2015

- Messages

- 229

- Location

- CenCoast CA

- V-Series Cadillac(s)?

- 2016 ATS-V Sedan, 2016 ATS-V Coupe

At this point, I have 1290 miles on the replacement engine in my 2016 Coupe. So far, there have been no problems with the installation. In addition to the new engine, at about the same time, my dealer, Bunnin Cadillac, as part of Cadillac's Premium Maintenance program, both the engine air filters and the cabin air filter were replaced.

At the 609 mile mark, I changed the oil for the first time. I always do the first oil change at 500-1000 miles on the engine to purge the oiling system of any silicone RTV residue which can cause oil foaming and to remove any debris from engine assembly which wasn't trapped by an oil filter and is lying on the bottom of the oil pan. Additionally, I don't think GM's Dexos 1 Generation 2 5W30 engine oil is the best choice for an engine like the LF4 which gets driven they way I run it.

My choice in engine oil is Driven Racing Oil's "DI30 Synthetic Direct Injection Performance Motor Oil" which is an mPAO-based 5W30 full synthetic formulated specifically for high-performance street direct injected gasoline engines. DI30 builds on Driven's successful LS30 high-performance engine oil with an improved DGI-specific additive package intended to address the tendency of turbocharged DGI engines to have problems with low-speed preignition (LSPI) and soot creation. To better explain LSPI, I've excerpted a "White Paper" Driven's head of research and development, Lake Speed wrote for Engine Professional magazine.

Thanks to Lake Speed and Driven Racing oil for permission to use their material in this blog post.

I'm using DI30 in my LF4 not only because its ability to reduce soot and LSPI, but also because DI30 uses a more robust mPAO base stock rather than the ordinary PAO base of Dexos 1 and Mobil 1. I prefer fully-synthetic engine oils, made from either Group-IV or Group-V base stocks because they are more stable under high-temperature (HTHS) conditions. My first oil change is a good time to replace a factory fill DI30, a Group-IV, mPAO-based, full-synthetic, 5W30 engine oil which I prefer run in the LF4 engine. Known as "SpectraSyn Elite" by its maker, ExxonMobil, "metallocene polyalphaolefin" or "mPAO" is described as: a high-performance polyalphaolefin (PAO) designed to provide better blending efficiency and performance capabilities than conventional synthetic PAO. These capabilities include: improved viscosity index, for high performance at a wide temperature range; enhanced shear stability, for long drain intervals and better low-temperature properties, for cold-start capability and fluidity. Ironically, ExxonMobil does not use its mPAO base stock in the Mobil 1 products it markets in North America. The mass-marketed Mobil 1 as well as Dexos 1 uses a Group III base stock.

Driven DI30's mPAO base stock performs better under HTHS conditions which may exist in high-performance, turbocharged engines when they are driven aggressively in hot weather.

As for oil filters, I use the ACDelco PF63E and I change them at 50% and zero engine oil life

At the 609 mile mark, I changed the oil for the first time. I always do the first oil change at 500-1000 miles on the engine to purge the oiling system of any silicone RTV residue which can cause oil foaming and to remove any debris from engine assembly which wasn't trapped by an oil filter and is lying on the bottom of the oil pan. Additionally, I don't think GM's Dexos 1 Generation 2 5W30 engine oil is the best choice for an engine like the LF4 which gets driven they way I run it.

My choice in engine oil is Driven Racing Oil's "DI30 Synthetic Direct Injection Performance Motor Oil" which is an mPAO-based 5W30 full synthetic formulated specifically for high-performance street direct injected gasoline engines. DI30 builds on Driven's successful LS30 high-performance engine oil with an improved DGI-specific additive package intended to address the tendency of turbocharged DGI engines to have problems with low-speed preignition (LSPI) and soot creation. To better explain LSPI, I've excerpted a "White Paper" Driven's head of research and development, Lake Speed wrote for Engine Professional magazine.

LSPI occurs in turbocharged direct injected engines because of the higher cylinder pressures present and because of the shorter amount of time the fuel has to vaporize. A typical GDI engine has less than 160 degrees of crankshaft rotation to atomize the fuel compared to over 320 degrees of crankshaft rotation to atomize the fuel in a traditional port injection or carbureted engine. The combination of higher compression and shorter atomization time make direct injection engines more prone to abnormal combustion events such as LSPI.

Internal combustion engines don’t burn liquid fuel. They “vaporize” the liquid gasoline by spraying the fuel as a fine mist into the hot and turbulent air moving through the engine. This process is typically called atomization, and it is simply the conversion of the fuel from a liquid state into a vapor. If the fuel doesn’t turn into a vapor, then the engine can’t burn it. Some of that unburnt fuel finds its way into the crevice between the top of the piston and the upper ring land where it mixes with the motor oil that lubricates the cylinder walls. This mixing is where things begin to go bad chemically.

How does oil chemistry effect things?

Gasoline direct injection engines create soot, just like a Diesel. The soot created in a DI engine can lead to increased abrasive wear greater than in a port injected or carbonated engine. Because DI engines offer both fuel economy and emissions advantages, the US Department of Energy made a research grant to Oak Ridge National Laboratory to investigate ways to overcome the limitations of DI engines with mainstream motor oil chemistry. These challenges pushed Oak Ridge to seek a lubricant development partner that could be nimble and had a keen understanding of engine hardware. This led Oak Ridge Driven Racing Oil to provide custom formulated motor oils.

The efforts of this partnership found that reducing the amount of Calcium detergent and eliminating the Sodium detergent in the motor oil formula reduced the frequency and severity of LSPI events. Once the main culprits, Calcium and Sodium based detergent additives, where identified, research began to understand why these additives contributed to LSPI. It is believed that Calcium and Sodium detergents chemically react with the fuel to create a third chemical which is neither gasoline nor engine oil. This third chemical has a lower octane value than either the fuel or the motor oil, so its detonation resistance, or antiknock rating is significantly lower. Because of the lower detonation resistance of this “blended” molecule, abnormal combustion results, which we call Low Speed Pre-Ignition. This was proven out by blending oil formulas that eliminated Sodium detergents and greatly reduced Calcium detergents. These research formulas also eliminated LSPI events.

This was a key finding, but it also presents a problem for the vast majority of off-the-shelf motor oils. Because calcium based detergents are the most cost effective detergents, calcium based detergents are widely used detergents in off-the-shelf motor oils, typically in high concentrations.

You may be wondering why the focus is on low engine speed. That is a fair question. At low engine speeds the turbulence of the intake charge is less than at higher engine speed. The lower turbulence leads to less atomization “assistance” by the intake charge. Imagine an engine running at idle at a stop light. The engine speed is low and there is no load on the engine. In this scenario, the fuel charge has less turbulence to assist atomization/vaporization as well as lower piston temperatures due to lower engine loads. Both reduced turbulence and lower piston temperatures work against atomization/vaporization of the fuel. Now add in back pressure from a turbocharger, and you have a recipe for reduced cylinder scavenging of a poorly atomized fuel charge. It is now wonder that DI experience higher levels of fuel dilution in used motor oil samples than port injection engines!

A long, low speed idle followed by a hard acceleration at full throttle is the perfect condition for an LSPI event – increased fuel dilution of the motor oil followed by high cylinder pressures.

Further proof of the atomization theory came recently from a test at EFI University. Working with Driven Racing Oil, EFI University has a GM LT1 Direct Injection engine at their testing facility. Utilizing the factory “knock” sensors to watch for early signs of possible LSPI events, Ben Strader and his team at EFI University tested two similar octane fuels – VP C10 and VP C20. While these fuels are very similar in octane, 100 octane for C10 and 98 octane for C20, the distillation curves of both fuels are drastically different.

Essentially, distillation is a measure of the ease of a liquid fuel to turn into a vapor. The higher the distillation temperatures, the more resistant the fuel is to vaporization. Conversely, the lower the distillation temperatures, the easier the fuel will vaporize.

Interestingly, the higher distillation temperatures of the C10 fuel caused the engine to “knock” more than the lower octane and lower distillation temperature C20 fuel. This increased knock due to lessened atomization/vaporization of the C10 fuel proved the theory of non-vaporized/liquid fuel contributing to abnormal combustion events like LSPI.

To address the soot and LSPI problems, Driven offers its line of DI specific oils – DI20, DI30, DI40 and DI60. All of these oils were built from the ground up to be compatible with turbocharged, direct injection engines. Lessons learned from Driven's partnership with Oak Ridge National Laboratory made its way into the Driven line of DI specific engine oils.

Thanks to Lake Speed and Driven Racing oil for permission to use their material in this blog post.

I'm using DI30 in my LF4 not only because its ability to reduce soot and LSPI, but also because DI30 uses a more robust mPAO base stock rather than the ordinary PAO base of Dexos 1 and Mobil 1. I prefer fully-synthetic engine oils, made from either Group-IV or Group-V base stocks because they are more stable under high-temperature (HTHS) conditions. My first oil change is a good time to replace a factory fill DI30, a Group-IV, mPAO-based, full-synthetic, 5W30 engine oil which I prefer run in the LF4 engine. Known as "SpectraSyn Elite" by its maker, ExxonMobil, "metallocene polyalphaolefin" or "mPAO" is described as: a high-performance polyalphaolefin (PAO) designed to provide better blending efficiency and performance capabilities than conventional synthetic PAO. These capabilities include: improved viscosity index, for high performance at a wide temperature range; enhanced shear stability, for long drain intervals and better low-temperature properties, for cold-start capability and fluidity. Ironically, ExxonMobil does not use its mPAO base stock in the Mobil 1 products it markets in North America. The mass-marketed Mobil 1 as well as Dexos 1 uses a Group III base stock.

Driven DI30's mPAO base stock performs better under HTHS conditions which may exist in high-performance, turbocharged engines when they are driven aggressively in hot weather.

As for oil filters, I use the ACDelco PF63E and I change them at 50% and zero engine oil life

Last edited:

Unclevito

Member

At this point, I have 1290 miles on the replacement engine in my 2016 Coupe. So far, there have been no problems with the installation. In addition to the new engine, at about the same time, my dealer, Bunnin Cadillac, as part of Cadillac's Premium Maintenance program, both the engine air filters and the cabin air filter were replaced.

At the 609 mile mark, I changed the oil for the first time. I always do the first oil change at 500-1000 miles on the engine to purge the oiling system of any silicone RTV residue which can cause oil foaming and to remove any debris from engine assembly which wasn't trapped by an oil filter and is lying on the bottom of the oil pan. Additionally, I don't think GM's Dexos 1 Generation 2 5W30 engine oil is the best choice for an engine like the LF4 which gets driven they way I run it.

My choice in engine oil is Driven Racing Oil's "DI30 Synthetic Direct Injection Performance Motor Oil" which is an mPAO-based 5W30 full synthetic formulated specifically for high-performance street direct injected gasoline engines. DI30 builds on Driven's successful LS30 high-performance engine oil with an improved DGI-specific additive package intended to address the tendency of turbocharged DGI engines to have problems with low-speed preignition (LSPI) and soot creation. To better explain LSPI, I've excerpted a "White Paper" Driven's head of research and development, Lake Speed wrote for Engine Professional magazine.

View attachment 999

LSPI occurs in turbocharged direct injected engines because of the higher cylinder pressures present and because of the shorter amount of time the fuel has to vaporize. A typical GDI engine has less than 160 degrees of crankshaft rotation to atomize the fuel compared to over 320 degrees of crankshaft rotation to atomize the fuel in a traditional port injection or carbureted engine. The combination of higher compression and shorter atomization time make direct injection engines more prone to abnormal combustion events such as LSPI.

Internal combustion engines don’t burn liquid fuel. They “vaporize” the liquid gasoline by spraying the fuel as a fine mist into the hot and turbulent air moving through the engine. This process is typically called atomization, and it is simply the conversion of the fuel from a liquid state into a vapor. If the fuel doesn’t turn into a vapor, then the engine can’t burn it. Some of that unburnt fuel finds its way into the crevice between the top of the piston and the upper ring land where it mixes with the motor oil that lubricates the cylinder walls. This mixing is where things begin to go bad chemically.

How does oil chemistry effect things?

Gasoline direct injection engines create soot, just like a Diesel. The soot created in a DI engine can lead to increased abrasive wear greater than in a port injected or carbonated engine. Because DI engines offer both fuel economy and emissions advantages, the US Department of Energy made a research grant to Oak Ridge National Laboratory to investigate ways to overcome the limitations of DI engines with mainstream motor oil chemistry. These challenges pushed Oak Ridge to seek a lubricant development partner that could be nimble and had a keen understanding of engine hardware. This led Oak Ridge Driven Racing Oil to provide custom formulated motor oils.

The efforts of this partnership found that reducing the amount of Calcium detergent and eliminating the Sodium detergent in the motor oil formula reduced the frequency and severity of LSPI events. Once the main culprits, Calcium and Sodium based detergent additives, where identified, research began to understand why these additives contributed to LSPI. It is believed that Calcium and Sodium detergents chemically react with the fuel to create a third chemical which is neither gasoline nor engine oil. This third chemical has a lower octane value than either the fuel or the motor oil, so its detonation resistance, or antiknock rating is significantly lower. Because of the lower detonation resistance of this “blended” molecule, abnormal combustion results, which we call Low Speed Pre-Ignition. This was proven out by blending oil formulas that eliminated Sodium detergents and greatly reduced Calcium detergents. These research formulas also eliminated LSPI events.

This was a key finding, but it also presents a problem for the vast majority of off-the-shelf motor oils. Because calcium based detergents are the most cost effective detergents, calcium based detergents are widely used detergents in off-the-shelf motor oils, typically in high concentrations.

You may be wondering why the focus is on low engine speed. That is a fair question. At low engine speeds the turbulence of the intake charge is less than at higher engine speed. The lower turbulence leads to less atomization “assistance” by the intake charge. Imagine an engine running at idle at a stop light. The engine speed is low and there is no load on the engine. In this scenario, the fuel charge has less turbulence to assist atomization/vaporization as well as lower piston temperatures due to lower engine loads. Both reduced turbulence and lower piston temperatures work against atomization/vaporization of the fuel. Now add in back pressure from a turbocharger, and you have a recipe for reduced cylinder scavenging of a poorly atomized fuel charge. It is now wonder that DI experience higher levels of fuel dilution in used motor oil samples than port injection engines!

A long, low speed idle followed by a hard acceleration at full throttle is the perfect condition for an LSPI event – increased fuel dilution of the motor oil followed by high cylinder pressures.

Further proof of the atomization theory came recently from a test at EFI University. Working with Driven Racing Oil, EFI University has a GM LT1 Direct Injection engine at their testing facility. Utilizing the factory “knock” sensors to watch for early signs of possible LSPI events, Ben Strader and his team at EFI University tested two similar octane fuels – VP C10 and VP C20. While these fuels are very similar in octane, 100 octane for C10 and 98 octane for C20, the distillation curves of both fuels are drastically different.

Essentially, distillation is a measure of the ease of a liquid fuel to turn into a vapor. The higher the distillation temperatures, the more resistant the fuel is to vaporization. Conversely, the lower the distillation temperatures, the easier the fuel will vaporize.

Interestingly, the higher distillation temperatures of the C10 fuel caused the engine to “knock” more than the lower octane and lower distillation temperature C20 fuel. This increased knock due to lessened atomization/vaporization of the C10 fuel proved the theory of non-vaporized/liquid fuel contributing to abnormal combustion events like LSPI.

To address the soot and LSPI problems, Driven offers its line of DI specific oils – DI20, DI30, DI40 and DI60. All of these oils were built from the ground up to be compatible with turbocharged, direct injection engines. Lessons learned from Driven's partnership with Oak Ridge National Laboratory made its way into the Driven line of DI specific engine oils.

Thanks to Lake Speed and Driven Racing oil for permission to use their material in this blog post.

I'm using DI30 in my LF4 not only because its ability to reduce soot and LSPI, but also because DI30 uses a more robust mPAO base stock rather than the ordinary PAO base of Dexos 1 and Mobil 1. I prefer fully-synthetic engine oils, made from either Group-IV or Group-V base stocks because they are more stable under high-temperature (HTHS) conditions. My first oil change is a good time to replace a factory fill DI30, a Group-IV, mPAO-based, full-synthetic, 5W30 engine oil which I prefer run in the LF4 engine. Known as "SpectraSyn Elite" by its maker, ExxonMobil, "metallocene polyalphaolefin" or "mPAO" is described as: a high-performance polyalphaolefin (PAO) designed to provide better blending efficiency and performance capabilities than conventional synthetic PAO. These capabilities include: improved viscosity index, for high performance at a wide temperature range; enhanced shear stability, for long drain intervals and better low-temperature properties, for cold-start capability and fluidity. Ironically, ExxonMobil does not use its mPAO base stock in the Mobil 1 products it markets in North America. The mass-marketed Mobil 1 as well as Dexos 1 uses a Group III base stock.

Driven DI30's mPAO base stock performs better under HTHS conditions which may exist in high-performance, turbocharged engines when they are driven aggressively in hot weather.

As for oil filters, I use the ACDelco PF63E and I change them at 50% and zero engine oil life

I agree with your choice of motor oil. Never thought you would ditch Mobil 1. Wonder why Mobil 1 is so highly rated when it is not 100% synthetic and does not use group IV or V base oils. Wonder if DRIVEN is 100% synthetic. Likely not that important as long as they use the best base oils. Also liked their comments that using a high flow gauze air filter (K&N) requires more frequent changes of the oil filter due to the grit the air filter introduces into the engine. That is why I have always recommended and used factory paper filters. Their suggestion to change the oil filter frequently but keep the oil makes sense.

Last edited:

Hib Halverson

Technical Writer for Internet & Print Media

- Joined

- Mar 20, 2015

- Messages

- 229

- Location

- CenCoast CA

- V-Series Cadillac(s)?

- 2016 ATS-V Sedan, 2016 ATS-V Coupe

Sorry I took so long to reply. My bad. I've ignored this thread too long.

It's very-well marketed.

I am not a big Mobil 1 guy. Typically, I do not use it.I agree with your choice of motor oil. Never thought you would ditch Mobil 1.

Wonder why Mobil 1 is so highly rated

It's very-well marketed.

Driven Racing Oil uses an mPAO base. Ironically, the mPAO base stock was developed by Exxon-Mobil about five years ago but is not used in M1 products.when it is not 100% synthetic and does not use group IV or V base oils. Wonder if DRIVEN is 100% synthetic.(snip)

Hib Halverson

Technical Writer for Internet & Print Media

- Joined

- Mar 20, 2015

- Messages

- 229

- Location

- CenCoast CA

- V-Series Cadillac(s)?

- 2016 ATS-V Sedan, 2016 ATS-V Coupe

Finally...a V-Blog Update

It's been a long time since I've reported on the two ATS-Vs my Wife and I own.

My late '16 Coupe now has 28982 miles total and 6412 miles since the engine was replaced last year. Since then the car has been trouble free. After having to replace the powertrain from the engine back to the driveshaft under warranty at various times since I bought the car, it's nice to have almost a year of no warranty hassles. My fingers are x'ed for that trend to continue.

About all I've had to do to the Blue Bulletm other than drive it and enjoy it, is some service tasks. I ran the second engine 600 miles then changed to Driven DI30, as discussed above in #305 above. I changed the oil filter at 50% oil life. I changed the lube in the rear drive axle at 26953. As I've done for nearly 25 years, I lubricate most of the rear axles in the cars and truck my Wife and I own with Red Line Heavy Shockproof Gear Oil.

Red Line's Shockproof line is totally different from conventional petroleum gear lubricants and most synthetics because their viscosity characteristics are vastly improved. The teeth in hypoid drive axle gearsets and those in helical gear, manual transmissions require high viscosity at high temperatures to prevent metal-to-metal contact and low viscosity when cold to reduce fluid friction. The ShockProof chemistry reduces high temperature thinning, thus reducing wear during severe duty use. They also have a coefficient of friction that's nearly half that of a conventional gear oil. Those properties combine to offer temperature reductions of 25-75°F in race track or aggressive high-performance street use.

The Shockproof Gear Oils' unique formulation allow them to lubricate like high-viscosity gear oil but flow like a lower viscosity product. For example, Heavy Shockproof can be rated as an SAE 75W250 gear oil, but has the fluid friction of a 75W90. LightWeight Shockproof can be rated as a 75W140 Gear Oil, but has the fluid friction of an SAE 30 motor oil. SuperLight Shockproof rates as a 70W90, but has the fluid friction of an ATF.

ShockProof provides greater viscosity in the thin layer of lubricant between gear teeth, but its low internal fluid friction means less power loss for the reliability and durability achieved. Under moderate loads, such as high-performance street use, the Shockproof gear oils can reduce wear by as much as a factor of ten. Under heavy loads, such as racing in hot weather, compared to petroleum-based gear oils, the Shockproof products can reduce wear by a factor of three and, compared to most other synthetic gear lubricants, by a factor of two.

Two real-world demonstrations of the value of the Shockproof chemistry's ability to lubricate the extreme pressure regions of gear systems are Top Fuel drag racing and off-road truck racing. Both these types of motorsports apply severe shock loadings to drive axles. Red Line Heavy Shockproof Gear Oil is the choice of most leading race teams which compete in them. In fact, the original Heavy Shockproof formulation came from off-road truck racing as a way solve drive axle failure due to the driveline shock loading which comes when race trucks get airborne, suddenly unloading, then abruptly reloading their drivelines.

In my ATS-V rear drive axles, Red Line Heavy Shockproof is a great product to use. While it is of no value in an ATS-V because they have electronically-controlled differential clutches which are external to the rear axle, Red Line HSP, has a friction modifier blended into it, so it can be usually be used in a rear axle having a mechanical limited slip differential without using any limited slip additive. In addition to HSP, use SuperLight Shockproof Gear Oil in the Blue Bullet's TR6060 six-speed. It reduces trans temperature and shift effort and improves shift feel Want to know more? Visit Red Line's Shockproof page.

It's been a long time since I've reported on the two ATS-Vs my Wife and I own.

My late '16 Coupe now has 28982 miles total and 6412 miles since the engine was replaced last year. Since then the car has been trouble free. After having to replace the powertrain from the engine back to the driveshaft under warranty at various times since I bought the car, it's nice to have almost a year of no warranty hassles. My fingers are x'ed for that trend to continue.

About all I've had to do to the Blue Bulletm other than drive it and enjoy it, is some service tasks. I ran the second engine 600 miles then changed to Driven DI30, as discussed above in #305 above. I changed the oil filter at 50% oil life. I changed the lube in the rear drive axle at 26953. As I've done for nearly 25 years, I lubricate most of the rear axles in the cars and truck my Wife and I own with Red Line Heavy Shockproof Gear Oil.

Red Line's Shockproof line is totally different from conventional petroleum gear lubricants and most synthetics because their viscosity characteristics are vastly improved. The teeth in hypoid drive axle gearsets and those in helical gear, manual transmissions require high viscosity at high temperatures to prevent metal-to-metal contact and low viscosity when cold to reduce fluid friction. The ShockProof chemistry reduces high temperature thinning, thus reducing wear during severe duty use. They also have a coefficient of friction that's nearly half that of a conventional gear oil. Those properties combine to offer temperature reductions of 25-75°F in race track or aggressive high-performance street use.

The Shockproof Gear Oils' unique formulation allow them to lubricate like high-viscosity gear oil but flow like a lower viscosity product. For example, Heavy Shockproof can be rated as an SAE 75W250 gear oil, but has the fluid friction of a 75W90. LightWeight Shockproof can be rated as a 75W140 Gear Oil, but has the fluid friction of an SAE 30 motor oil. SuperLight Shockproof rates as a 70W90, but has the fluid friction of an ATF.

ShockProof provides greater viscosity in the thin layer of lubricant between gear teeth, but its low internal fluid friction means less power loss for the reliability and durability achieved. Under moderate loads, such as high-performance street use, the Shockproof gear oils can reduce wear by as much as a factor of ten. Under heavy loads, such as racing in hot weather, compared to petroleum-based gear oils, the Shockproof products can reduce wear by a factor of three and, compared to most other synthetic gear lubricants, by a factor of two.

Two real-world demonstrations of the value of the Shockproof chemistry's ability to lubricate the extreme pressure regions of gear systems are Top Fuel drag racing and off-road truck racing. Both these types of motorsports apply severe shock loadings to drive axles. Red Line Heavy Shockproof Gear Oil is the choice of most leading race teams which compete in them. In fact, the original Heavy Shockproof formulation came from off-road truck racing as a way solve drive axle failure due to the driveline shock loading which comes when race trucks get airborne, suddenly unloading, then abruptly reloading their drivelines.

In my ATS-V rear drive axles, Red Line Heavy Shockproof is a great product to use. While it is of no value in an ATS-V because they have electronically-controlled differential clutches which are external to the rear axle, Red Line HSP, has a friction modifier blended into it, so it can be usually be used in a rear axle having a mechanical limited slip differential without using any limited slip additive. In addition to HSP, use SuperLight Shockproof Gear Oil in the Blue Bullet's TR6060 six-speed. It reduces trans temperature and shift effort and improves shift feel Want to know more? Visit Red Line's Shockproof page.

Last edited:

Hib Halverson

Technical Writer for Internet & Print Media

- Joined

- Mar 20, 2015

- Messages

- 229

- Location

- CenCoast CA

- V-Series Cadillac(s)?

- 2016 ATS-V Sedan, 2016 ATS-V Coupe

Another New Engine

Ok, now...let's check-in on my other ATS-V, the early-'16 four-door my Wife, the Fairest Sandra the Red, drives. That's been another warranty problem-child. Like the Blue Bullet, my six-speed Coupe, it had to have it's engine replaced due to the oil smoke after cold start problem. In fact, because this was before GM understood the cause of that problem, GM first had my dealer, Bunnin Cadillac of Santa Barbara CA, replace the cylinder heads. That didn't fix it. Then, they replaced the turbos. That didn't fit it. Finally, they put a motor in it at 35842 miles.

You'd think that would have solved the problem as bore scope testing at the dealer level and disassembly of the warranty return engine back in Michigan showed that the problem was caused by failures of some of the cylinder walls. Well, the engine went another 17704 miles and failed again with exactly the same problem.

Turns out what was causing the bore walls to loose ring seal was abrasive material left inside the lower intake manifold during manufacturing by the GM supplier of the manifold. GM determined that after our four-door's engine was replaced but before the engine was replaced in my Coupe. Because no one at GM knew the cause, thus, GM did not instruct the dealer to replace nor to clean the manifold. As GM not only pays a lower hourly rate for warranty work and pressures dealers to do warranty repairs quickly, dealer techs did not disassemble and clean the manifold. They put the old manifold when back on which still had debris inside. The engine just sucked more of that stuff in, destroyed its ring seal and started smoking after cold starts, again.

Same old symptoms. Turbocharger turbine wheel wet with oil.

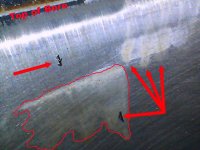

The lower intake manifold. This one goes into the scrap pile.

The car has been sitting at our dealer for more than a month. We had to take it in to let them diagnose it. Then, we had to wait for a GM Field Service Engineer and the GM Technical Assistance Center to approve a second engine change. The replacement engine came quickly but there were some other parts needed which did not arrive in a timely manner due to the China Virus, so the car continued to sit in the dealer's back lot. But wait...there's more. Once all the parts finally arrived and the Technician who works on my stuff, Luis Rios, opened up the crate and looked at the engine, he decided it was not acceptable, so we waited another week for another new engine while the car tied up Luis' rack.

The front tires, front suspension, and exhaust have to come out before the engine can be removed. Like many modern cars,

an ATS-V's engine is bottom loaded.

The new, new engine arrived last Thursday and they'll begin work replacing the "old, new engine" on Monday.

The new engine ready to go. Currently, GM has no LF4s for automatic cars, so it ships manual trans engines and

dealer techs have to remove the flywheel/clutch assembly and replace it with an automatic trans. flex plate.

I tell you, GM has lost a ton of money on our two ATS-Vs. Here's the list of major parts which have failed and been replaced.

Two cylinder heads

Two turbochargers

Three engines

One flywheel/clutch assembly

One six-speed manual transmission

One prop shaft

You just can't make this s**t up.

But, the glutton for punishment, I am, I still really like driving an ATS-V. The power, handing, braking and rear-drive configuration really suits my tastes in a daily driver.

Ok, now...let's check-in on my other ATS-V, the early-'16 four-door my Wife, the Fairest Sandra the Red, drives. That's been another warranty problem-child. Like the Blue Bullet, my six-speed Coupe, it had to have it's engine replaced due to the oil smoke after cold start problem. In fact, because this was before GM understood the cause of that problem, GM first had my dealer, Bunnin Cadillac of Santa Barbara CA, replace the cylinder heads. That didn't fix it. Then, they replaced the turbos. That didn't fit it. Finally, they put a motor in it at 35842 miles.

You'd think that would have solved the problem as bore scope testing at the dealer level and disassembly of the warranty return engine back in Michigan showed that the problem was caused by failures of some of the cylinder walls. Well, the engine went another 17704 miles and failed again with exactly the same problem.

Turns out what was causing the bore walls to loose ring seal was abrasive material left inside the lower intake manifold during manufacturing by the GM supplier of the manifold. GM determined that after our four-door's engine was replaced but before the engine was replaced in my Coupe. Because no one at GM knew the cause, thus, GM did not instruct the dealer to replace nor to clean the manifold. As GM not only pays a lower hourly rate for warranty work and pressures dealers to do warranty repairs quickly, dealer techs did not disassemble and clean the manifold. They put the old manifold when back on which still had debris inside. The engine just sucked more of that stuff in, destroyed its ring seal and started smoking after cold starts, again.

Same old symptoms. Turbocharger turbine wheel wet with oil.

The lower intake manifold. This one goes into the scrap pile.

The car has been sitting at our dealer for more than a month. We had to take it in to let them diagnose it. Then, we had to wait for a GM Field Service Engineer and the GM Technical Assistance Center to approve a second engine change. The replacement engine came quickly but there were some other parts needed which did not arrive in a timely manner due to the China Virus, so the car continued to sit in the dealer's back lot. But wait...there's more. Once all the parts finally arrived and the Technician who works on my stuff, Luis Rios, opened up the crate and looked at the engine, he decided it was not acceptable, so we waited another week for another new engine while the car tied up Luis' rack.

The front tires, front suspension, and exhaust have to come out before the engine can be removed. Like many modern cars,

an ATS-V's engine is bottom loaded.

The new, new engine arrived last Thursday and they'll begin work replacing the "old, new engine" on Monday.

The new engine ready to go. Currently, GM has no LF4s for automatic cars, so it ships manual trans engines and

dealer techs have to remove the flywheel/clutch assembly and replace it with an automatic trans. flex plate.

I tell you, GM has lost a ton of money on our two ATS-Vs. Here's the list of major parts which have failed and been replaced.

Two cylinder heads

Two turbochargers

Three engines

One flywheel/clutch assembly

One six-speed manual transmission

One prop shaft

You just can't make this s**t up.

But, the glutton for punishment, I am, I still really like driving an ATS-V. The power, handing, braking and rear-drive configuration really suits my tastes in a daily driver.

Hib Halverson

Technical Writer for Internet & Print Media

- Joined

- Mar 20, 2015

- Messages

- 229

- Location

- CenCoast CA

- V-Series Cadillac(s)?

- 2016 ATS-V Sedan, 2016 ATS-V Coupe

Finally!

Our '16 Sedan, "Pearl, is back on the road with its third engine. My Wife, the Fairest Sandra the Red, has about 100 miles on it with no problems and she's happy to have her car back after a couple of months parked on the dealer's back lot waiting for parts.

With this engine replacement, because the only replacement LF4s GM has available are manual trans versions, the Service Technician who did the work at Bunnin Cadillac, Luis Rios, had to remove the flywheel/clutch assembly, switch oil pans then install the flexplate for the 8L90 eight-speed auto we have in that car. When I asked Luis what was going to happen with the clutch, he told me in cases where parts have to be swapped onto new engines, the parts that come off get scrapped. "Oh, no, no no." I thought then walked over to the Parts Manager to plead my case. In the end, I got the flywheel, clutch and disc to keep as spares for our other ATS-V which is a six-speed manual.

The oil pan swap allowed us to inspect and photograph the inside of the pan after it was removed, something we were not able to do with the first engine replacement.

Since this oil smoke problem has been a three-plus-year saga, I'm posted a lot about it, both here on the Little V-Blog and also in several threads in the ATS-V forum on the Cadillac Forum site. While at this point, it's been well documented that this is a cylinder bore wall problem, there still have been posts suggesting the cause of a problem demonstrating those symptoms is something else, such as valve stem seals, turbos or some other issue. Additionally, back in 2016, when the problem first cropped up with Pearl's original engine, even GM was not sure what was causing it.

These pictures of the inside of the oil pan and the windage tray should put to rest any of those other potential causes. There is a dark gray, sort of fine-grained residue left on the parts in areas where oil has drained away. That is iron a very fine iron residue worn off the bore walls.

Before the second engine was removed, its cylinders were borescope and in the borescope image below, shot by Luis Rios, you can see the unusual bore wear caused by the debris left in the intake manifold.

The car now has just a hair under 55,000 miles on it. With its third engine, and this time with a new intake manifold, hopefully, this will be the last time we ever see oil smoke from this car.

Thanks to Bunnin Cadillac, Service Advisor, Diego Benrostro, Service Manager, Russ Stevenson and, especially, Service Technician, Luis Rios, for all the support these given Sandy and I in stating our case with General Motors.

Our '16 Sedan, "Pearl, is back on the road with its third engine. My Wife, the Fairest Sandra the Red, has about 100 miles on it with no problems and she's happy to have her car back after a couple of months parked on the dealer's back lot waiting for parts.

With this engine replacement, because the only replacement LF4s GM has available are manual trans versions, the Service Technician who did the work at Bunnin Cadillac, Luis Rios, had to remove the flywheel/clutch assembly, switch oil pans then install the flexplate for the 8L90 eight-speed auto we have in that car. When I asked Luis what was going to happen with the clutch, he told me in cases where parts have to be swapped onto new engines, the parts that come off get scrapped. "Oh, no, no no." I thought then walked over to the Parts Manager to plead my case. In the end, I got the flywheel, clutch and disc to keep as spares for our other ATS-V which is a six-speed manual.

The oil pan swap allowed us to inspect and photograph the inside of the pan after it was removed, something we were not able to do with the first engine replacement.

Since this oil smoke problem has been a three-plus-year saga, I'm posted a lot about it, both here on the Little V-Blog and also in several threads in the ATS-V forum on the Cadillac Forum site. While at this point, it's been well documented that this is a cylinder bore wall problem, there still have been posts suggesting the cause of a problem demonstrating those symptoms is something else, such as valve stem seals, turbos or some other issue. Additionally, back in 2016, when the problem first cropped up with Pearl's original engine, even GM was not sure what was causing it.

These pictures of the inside of the oil pan and the windage tray should put to rest any of those other potential causes. There is a dark gray, sort of fine-grained residue left on the parts in areas where oil has drained away. That is iron a very fine iron residue worn off the bore walls.

Before the second engine was removed, its cylinders were borescope and in the borescope image below, shot by Luis Rios, you can see the unusual bore wear caused by the debris left in the intake manifold.

The car now has just a hair under 55,000 miles on it. With its third engine, and this time with a new intake manifold, hopefully, this will be the last time we ever see oil smoke from this car.

Thanks to Bunnin Cadillac, Service Advisor, Diego Benrostro, Service Manager, Russ Stevenson and, especially, Service Technician, Luis Rios, for all the support these given Sandy and I in stating our case with General Motors.

jlettiere

New Member

Good morning -

After performing initial tests, Cadillac agreed to replace my engine. There was no push-back from the dealer (Sunset Cadillac of Venice FL) or Cadillac engineering.

The engine arrived in 3 days. The crate sent from Cadillac included the base engine, manifolds, PVC system plumbing, etc. They did not replace the cats because the V had only 21,000 miles on it.

Everything was disassembled and re-installed in 2.5 days. They took an extra day to run diagnostics, check cold start and fluid levels. I got my V back yesterday. The V is running great, no start up smoke, engine codes or "new rattles and squeaks". It was a very painless process made possible by the dealer service rep, master techs and loaner car staff.

At first, I was really reluctant to get this done. But after speaking with the serve rep and master techs in the shop, I felt confident that they would do a meticulous job..... and they did!

Without the ATS-V and Cadillac ATS forums and the persistence of Hib_Halversonon this issue, I doubt that I would have been successful in getting this problem corrected.

I thank everyone who has participated in the discussion over the years and for sharing your expertise and experience.

Jack

After performing initial tests, Cadillac agreed to replace my engine. There was no push-back from the dealer (Sunset Cadillac of Venice FL) or Cadillac engineering.

The engine arrived in 3 days. The crate sent from Cadillac included the base engine, manifolds, PVC system plumbing, etc. They did not replace the cats because the V had only 21,000 miles on it.

Everything was disassembled and re-installed in 2.5 days. They took an extra day to run diagnostics, check cold start and fluid levels. I got my V back yesterday. The V is running great, no start up smoke, engine codes or "new rattles and squeaks". It was a very painless process made possible by the dealer service rep, master techs and loaner car staff.

At first, I was really reluctant to get this done. But after speaking with the serve rep and master techs in the shop, I felt confident that they would do a meticulous job..... and they did!

Without the ATS-V and Cadillac ATS forums and the persistence of Hib_Halversonon this issue, I doubt that I would have been successful in getting this problem corrected.

I thank everyone who has participated in the discussion over the years and for sharing your expertise and experience.

Jack

Unclevito

Member

"The mass-marketed Mobil 1 as well as Dexos 1 uses a Group III base stock.". Bingo. I get into arguments with folks when I suggest to them that they drain out Mobil 1 and put in a better oil that is not base III stock. Thanks for the excerpt from Driven oil.At this point, I have 1290 miles on the replacement engine in my 2016 Coupe. So far, there have been no problems with the installation. In addition to the new engine, at about the same time, my dealer, Bunnin Cadillac, as part of Cadillac's Premium Maintenance program, both the engine air filters and the cabin air filter were replaced.

At the 609 mile mark, I changed the oil for the first time. I always do the first oil change at 500-1000 miles on the engine to purge the oiling system of any silicone RTV residue which can cause oil foaming and to remove any debris from engine assembly which wasn't trapped by an oil filter and is lying on the bottom of the oil pan. Additionally, I don't think GM's Dexos 1 Generation 2 5W30 engine oil is the best choice for an engine like the LF4 which gets driven they way I run it.

My choice in engine oil is Driven Racing Oil's "DI30 Synthetic Direct Injection Performance Motor Oil" which is an mPAO-based 5W30 full synthetic formulated specifically for high-performance street direct injected gasoline engines. DI30 builds on Driven's successful LS30 high-performance engine oil with an improved DGI-specific additive package intended to address the tendency of turbocharged DGI engines to have problems with low-speed preignition (LSPI) and soot creation. To better explain LSPI, I've excerpted a "White Paper" Driven's head of research and development, Lake Speed wrote for Engine Professional magazine.

View attachment 999

LSPI occurs in turbocharged direct injected engines because of the higher cylinder pressures present and because of the shorter amount of time the fuel has to vaporize. A typical GDI engine has less than 160 degrees of crankshaft rotation to atomize the fuel compared to over 320 degrees of crankshaft rotation to atomize the fuel in a traditional port injection or carbureted engine. The combination of higher compression and shorter atomization time make direct injection engines more prone to abnormal combustion events such as LSPI.Internal combustion engines don’t burn liquid fuel. They “vaporize” the liquid gasoline by spraying the fuel as a fine mist into the hot and turbulent air moving through the engine. This process is typically called atomization, and it is simply the conversion of the fuel from a liquid state into a vapor. If the fuel doesn’t turn into a vapor, then the engine can’t burn it. Some of that unburnt fuel finds its way into the crevice between the top of the piston and the upper ring land where it mixes with the motor oil that lubricates the cylinder walls. This mixing is where things begin to go bad chemically.How does oil chemistry effect things?Gasoline direct injection engines create soot, just like a Diesel. The soot created in a DI engine can lead to increased abrasive wear greater than in a port injected or carbonated engine. Because DI engines offer both fuel economy and emissions advantages, the US Department of Energy made a research grant to Oak Ridge National Laboratory to investigate ways to overcome the limitations of DI engines with mainstream motor oil chemistry. These challenges pushed Oak Ridge to seek a lubricant development partner that could be nimble and had a keen understanding of engine hardware. This led Oak Ridge Driven Racing Oil to provide custom formulated motor oils. The efforts of this partnership found that reducing the amount of Calcium detergent and eliminating the Sodium detergent in the motor oil formula reduced the frequency and severity of LSPI events. Once the main culprits, Calcium and Sodium based detergent additives, where identified, research began to understand why these additives contributed to LSPI. It is believed that Calcium and Sodium detergents chemically react with the fuel to create a third chemical which is neither gasoline nor engine oil. This third chemical has a lower octane value than either the fuel or the motor oil, so its detonation resistance, or antiknock rating is significantly lower. Because of the lower detonation resistance of this “blended” molecule, abnormal combustion results, which we call Low Speed Pre-Ignition. This was proven out by blending oil formulas that eliminated Sodium detergents and greatly reduced Calcium detergents. These research formulas also eliminated LSPI events.This was a key finding, but it also presents a problem for the vast majority of off-the-shelf motor oils. Because calcium based detergents are the most cost effective detergents, calcium based detergents are widely used detergents in off-the-shelf motor oils, typically in high concentrations.You may be wondering why the focus is on low engine speed. That is a fair question. At low engine speeds the turbulence of the intake charge is less than at higher engine speed. The lower turbulence leads to less atomization “assistance” by the intake charge. Imagine an engine running at idle at a stop light. The engine speed is low and there is no load on the engine. In this scenario, the fuel charge has less turbulence to assist atomization/vaporization as well as lower piston temperatures due to lower engine loads. Both reduced turbulence and lower piston temperatures work against atomization/vaporization of the fuel. Now add in back pressure from a turbocharger, and you have a recipe for reduced cylinder scavenging of a poorly atomized fuel charge. It is now wonder that DI experience higher levels of fuel dilution in used motor oil samples than port injection engines!A long, low speed idle followed by a hard acceleration at full throttle is the perfect condition for an LSPI event – increased fuel dilution of the motor oil followed by high cylinder pressures. Further proof of the atomization theory came recently from a test at EFI University. Working with Driven Racing Oil, EFI University has a GM LT1 Direct Injection engine at their testing facility. Utilizing the factory “knock” sensors to watch for early signs of possible LSPI events, Ben Strader and his team at EFI University tested two similar octane fuels – VP C10 and VP C20. While these fuels are very similar in octane, 100 octane for C10 and 98 octane for C20, the distillation curves of both fuels are drastically different.Essentially, distillation is a measure of the ease of a liquid fuel to turn into a vapor. The higher the distillation temperatures, the more resistant the fuel is to vaporization. Conversely, the lower the distillation temperatures, the easier the fuel will vaporize. Interestingly, the higher distillation temperatures of the C10 fuel caused the engine to “knock” more than the lower octane and lower distillation temperature C20 fuel. This increased knock due to lessened atomization/vaporization of the C10 fuel proved the theory of non-vaporized/liquid fuel contributing to abnormal combustion events like LSPI. To address the soot and LSPI problems, Driven offers its line of DI specific oils – DI20, DI30, DI40 and DI60. All of these oils were built from the ground up to be compatible with turbocharged, direct injection engines. Lessons learned from Driven's partnership with Oak Ridge National Laboratory made its way into the Driven line of DI specific engine oils.

Thanks to Lake Speed and Driven Racing oil for permission to use their material in this blog post.

I'm using DI30 in my LF4 not only because its ability to reduce soot and LSPI, but also because DI30 uses a more robust mPAO base stock rather than the ordinary PAO base of Dexos 1 and Mobil 1. I prefer fully-synthetic engine oils, made from either Group-IV or Group-V base stocks because they are more stable under high-temperature (HTHS) conditions. My first oil change is a good time to replace a factory fill DI30, a Group-IV, mPAO-based, full-synthetic, 5W30 engine oil which I prefer run in the LF4 engine. Known as "SpectraSyn Elite" by its maker, ExxonMobil, "metallocene polyalphaolefin" or "mPAO" is described as: a high-performance polyalphaolefin (PAO) designed to provide better blending efficiency and performance capabilities than conventional synthetic PAO. These capabilities include: improved viscosity index, for high performance at a wide temperature range; enhanced shear stability, for long drain intervals and better low-temperature properties, for cold-start capability and fluidity. Ironically, ExxonMobil does not use its mPAO base stock in the Mobil 1 products it markets in North America. The mass-marketed Mobil 1 as well as Dexos 1 uses a Group III base stock.

Driven DI30's mPAO base stock performs better under HTHS conditions which may exist in high-performance, turbocharged engines when they are driven aggressively in hot weather.

As for oil filters, I use the ACDelco PF63E and I change them at 50% and zero engine oil life

Last edited:

NorthGeorgiaWX

Member

- Joined

- Aug 1, 2021

- Messages

- 17

- Location

- Big Canoe Georgia

- V-Series Cadillac(s)?

- 2016 ATS-V sedan - 2017 ATS-V coupe

We own two ATS-V's, a 2017 coupe and a 2016 sedan. No issues with either car other than the carbon fiber is coming off the passenger door on my coupe. The sedan has ~60k miles and the coupe 22k and both cars are heavily modified.

I run Mobil 1 in both cars and have no issues with it. Change your oil often with any good oil and you won't have any issues. One of our cars is autocrossed and tracked so the oil and filter are changed often.

Not sure why Hib has so many issues. I know the 16's had some issues, but these cars have been bulletproof for us. One's making ~720 whp and the other 630 whp so it's not like they are lightly stressed.

I run Mobil 1 in both cars and have no issues with it. Change your oil often with any good oil and you won't have any issues. One of our cars is autocrossed and tracked so the oil and filter are changed often.

Not sure why Hib has so many issues. I know the 16's had some issues, but these cars have been bulletproof for us. One's making ~720 whp and the other 630 whp so it's not like they are lightly stressed.

Attachments

jlettiere

New Member

My 2016 V w/ auto trans threw a Fault Code P16E7 last week. I was travelling at 75mph and hit the accelerator to get into the passing lane. The code cleared itself, so I went out to try to replicate the condition. It threw the P16E7 code again under the "same" conditions. BTW, I could never get the code to light up under any other speed/ turbo boost conditions.

The dealer master tech has been working with Cadillac engineering. The dealer

s initial tests of vacuum leaks, Vacuum pump, Vacuum Tank, Turbocharger Bypass Solenoid Valve, Turbocharger Wastegate Solenoid Valve and turbos have not shown any problems. Cadillac Tech now has the freeze frames for their analysis

Has anyone encountered this problem (P16E7)?

Any experience or knowledge would be helpful.

Thanks!

The dealer master tech has been working with Cadillac engineering. The dealer

s initial tests of vacuum leaks, Vacuum pump, Vacuum Tank, Turbocharger Bypass Solenoid Valve, Turbocharger Wastegate Solenoid Valve and turbos have not shown any problems. Cadillac Tech now has the freeze frames for their analysis

Has anyone encountered this problem (P16E7)?

Any experience or knowledge would be helpful.

Thanks!

WONT TAP

Seasoned Member

- Joined

- Jul 24, 2021

- Messages

- 621

- Location

- Columbus OH

- V-Series Cadillac(s)?

- 2016 ATS-V A8, 2018 ATS-V M6, 2022 CT4-V Blackwing A10

DTC P16E7 is a boost imbalance code. It could be something simple like a loose charge pipe hose clamp, broken charge pipe hose or damaged charge pipe gasket. It could also mean your black plastic vacuum manifold and/or one of the rubber fittings is cracked. Or it could indicate that one of your turbochargers has failed.My 2016 V w/ auto trans threw a Fault Code P16E7 last week. I was travelling at 75mph and hit the accelerator to get into the passing lane. The code cleared itself, so I went out to try to replicate the condition. It threw the P16E7 code again under the "same" conditions. BTW, I could never get the code to light up under any other speed/ turbo boost conditions.

The dealer master tech has been working with Cadillac engineering. The dealer

s initial tests of vacuum leaks, Vacuum pump, Vacuum Tank, Turbocharger Bypass Solenoid Valve, Turbocharger Wastegate Solenoid Valve and turbos have not shown any problems. Cadillac Tech now has the freeze frames for their analysis

Has anyone encountered this problem (P16E7)?

Any experience or knowledge would be helpful.

Thanks!

If you own HP Tuners, feel free to send a VCM Scanner data log to me directly at ScottC@TapoutTuning.com, and I will assist with diagnosis.

jlettiere

New Member

Scott, thank you so much for your response and offer to assist.

Two weeks ago, after performing a number of vacuum leak tests, reviewing freeze frame data etc., they saw in the freeze frame that there was a huge wastegate imbalance (95% bank 1 and 265 bank 2). A smoke test was performed on the vacuum solenoid to the turbo. That checked out OK. So, the Cadillac Field Engineer advised the Cadillac Service to replace the bank 2 wastegate solenoid.

After driving the vehicle for a week, the P16E7 DTC appeared again under the same conditions (at 75mph and hit the accelerator to get into the passing lane).

Back to the Cadillac shop next week...... wish me luck!

Two weeks ago, after performing a number of vacuum leak tests, reviewing freeze frame data etc., they saw in the freeze frame that there was a huge wastegate imbalance (95% bank 1 and 265 bank 2). A smoke test was performed on the vacuum solenoid to the turbo. That checked out OK. So, the Cadillac Field Engineer advised the Cadillac Service to replace the bank 2 wastegate solenoid.

After driving the vehicle for a week, the P16E7 DTC appeared again under the same conditions (at 75mph and hit the accelerator to get into the passing lane).

Back to the Cadillac shop next week...... wish me luck!

Kef2782

New Member

Curious to know what fixed your car? I've had the 16E7 code after installing downpipes, without resolve. The local Cadillac dealer took a crack at it (costing me 1k), changed a HPFP, before throwing their hands up stating it's too modified (CAI, DPs, and tune) for them to work onScott, thank you so much for your response and offer to assist.

Two weeks ago, after performing a number of vacuum leak tests, reviewing freeze frame data etc., they saw in the freeze frame that there was a huge wastegate imbalance (95% bank 1 and 265 bank 2). A smoke test was performed on the vacuum solenoid to the turbo. That checked out OK. So, the Cadillac Field Engineer advised the Cadillac Service to replace the bank 2 wastegate solenoid.

After driving the vehicle for a week, the P16E7 DTC appeared again under the same conditions (at 75mph and hit the accelerator to get into the passing lane).

Back to the Cadillac shop next week...... wish me luck!

WONT TAP

Seasoned Member

- Joined

- Jul 24, 2021

- Messages

- 621

- Location

- Columbus OH

- V-Series Cadillac(s)?

- 2016 ATS-V A8, 2018 ATS-V M6, 2022 CT4-V Blackwing A10

DTC P16E7 has nothing do

A defective turbo can cause this code, but it's rare. Far more often we see this code when someone installs a poorly engineered aftermarket intake that allows the MAF sensors to be swapped between banks or installed backwards. It could be something simple like a loose charge pipe hose clamp, broken charge pipe hose or damaged charge pipe gasket. Any type of leak in the vacuum circuit/reservoir that controls boost can also cause this, and since the reservoir is plastic it gets old and brittle and can crack over time. One other rare cause for those still running OEM catalytic converters with high mileage when one converter gets clogged (over 100,000 miles).

If you have HP Tuners, feel free to send a data scan showing the problem and I can assist with the diagnosis. My direct email address is ScottC@TapoutTuning.com. If you don't already own HP Tuners, definitely consider it, since it's the single best investment you can make.

DTC P16E7 indicates that the ECM has detected a boost imbalance. It has nothing to do with the HPFP. Sorry your situation was misdiagnosed.Curious to know what fixed your car? I've had the 16E7 code after installing downpipes, without resolve. The local Cadillac dealer took a crack at it (costing me 1k), changed a HPFP, before throwing their hands up stating it's too modified (CAI, DPs, and tune) for them to work on

A defective turbo can cause this code, but it's rare. Far more often we see this code when someone installs a poorly engineered aftermarket intake that allows the MAF sensors to be swapped between banks or installed backwards. It could be something simple like a loose charge pipe hose clamp, broken charge pipe hose or damaged charge pipe gasket. Any type of leak in the vacuum circuit/reservoir that controls boost can also cause this, and since the reservoir is plastic it gets old and brittle and can crack over time. One other rare cause for those still running OEM catalytic converters with high mileage when one converter gets clogged (over 100,000 miles).

If you have HP Tuners, feel free to send a data scan showing the problem and I can assist with the diagnosis. My direct email address is ScottC@TapoutTuning.com. If you don't already own HP Tuners, definitely consider it, since it's the single best investment you can make.

Kef2782

New Member

Tracking it has nothing to do with the HPFP, dealership argued that it the HPFP was suspected to be leaking so I elected to allow them to replace it (extended warranty covered most of it).

I was running my intake for over a year without issue, it was immediately after the DP install did I have the issue. They claimed they smoked the vacuum system but I followed up with my smoker but could not locate any leaks either

I was running my intake for over a year without issue, it was immediately after the DP install did I have the issue. They claimed they smoked the vacuum system but I followed up with my smoker but could not locate any leaks either

jlettiere

New Member

Well, my problem was solved. Cadillac field engineer had a turbo replaced. Car ran well but got the P167 back. Another field engineering team came out and came to the conclusion that the only thin not replaced was the MAF. They replaced the MAF. The V has run great since then. They took the MAF with them and responded to me a week later. They said the MAF was found to be "intermittently faulty." All fixed under warranty

Similar threads

- Replies

- 25

- Views

- 1K

- Replies

- 13

- Views

- 727