“Oil analysis”–if you’re an “advanced DIY”, you’ve probably heard the term. Proper nomenclature is “spectrographic oil analysis” and it’s been used for decades by oil companies, fleet operators, race engine builders and others who have a need to measure the condition of engine oil. The user sends a sample of oil to a spectrographic analysis laboratory, such as Blackstone Labs, where a portion of the oil sample is run through a spectrometer. That device analyzes the oil and gives the levels of the various metals and additives which are present in the oil. Those levels are a measure of how much your engine is wearing. The rest of the sample is used for other testing. An insolubles test measures the amount of abrasive solids present in the oil. The solids are formed by oil oxidation and blow-by. A viscosity test measures the grade, or thickness, of the oil. Whether it’s supposed to be a 5W/30, 15W/40, or some other grade, the lab will know, within a range, what the viscosity should be. Finally, a flash point test measures the temperature at which vapors from the oil ignite. For any specific grade of oil, the flash temperature is known. If the sample flashes at or above that level, the oil is not contaminated. If the oil flashes off lower than it should, then it’s probably been contaminated. Fuel is the most common contaminant in oil.

Spectrographic oil analysis, for all its advantages, cannot detect “large” pieces of debris in the oil. In this case “large” refers to those particles which are bigger than the microscopic sized material–generally stuff smaller than 20-microns (micron=a millionth of a meter or about four one-hundred-thousandths of an inch)–which goes though oil filters and which spectrographic oil analysis measures.

Of these larger particles, there are the “kinda large” ones which are 20-100 microns in size and which get trapped by the filter, but are difficult to see without a microscope. Then, there are the really “huge” ones which are over 100 microns and up to .010-inch or so which the oil filter traps and you can see easily. Anything larger than that gets stopped by the screen on the oil pump pick-up. How do you “analyze” your oil in a manner which will detect debris too small to be stopped by the pump’s oil screen, but are large enough to get trapped by the oil filter and are visible?

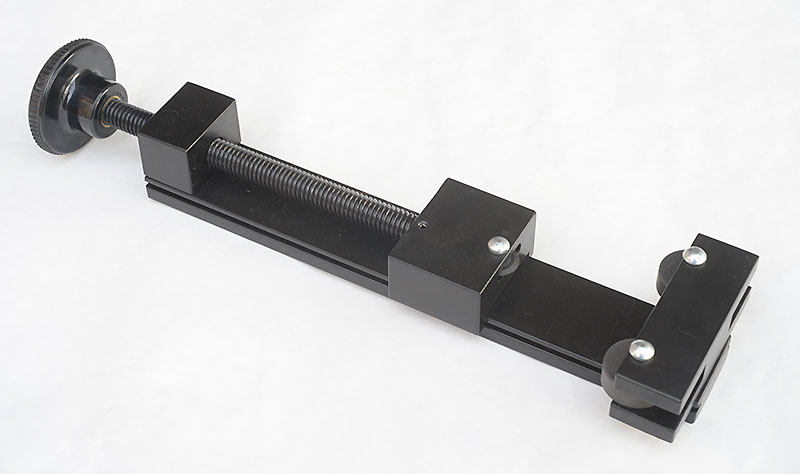

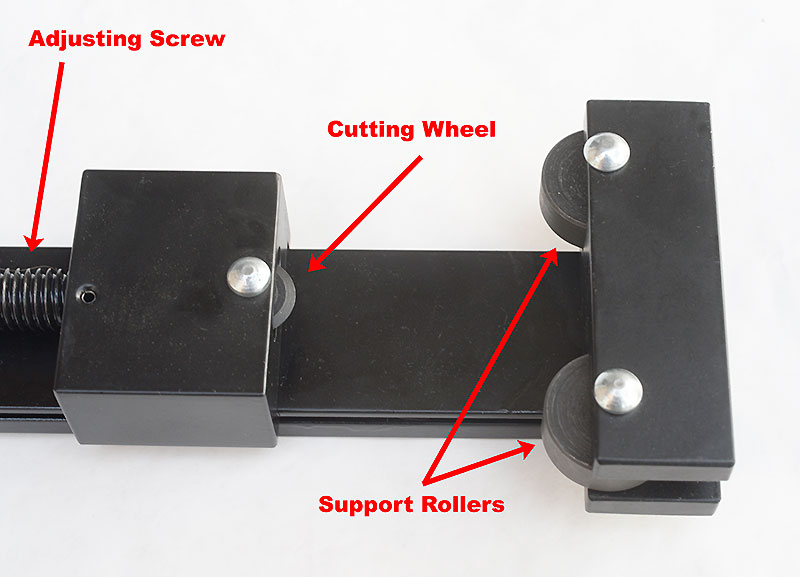

You cut the filter open and visually inspect the filter media, but you can’t do that with a hacksaw or a pair of shears. You need a special tool called an “oil filter cutter”. There are a number of these filter cutters on the market and, expectedly, they vary in price from relatively inexpensive to quite costly. We went looking for a filter cutter of reasonable cost and found one at Summit Racing Equipment. Summit’s filter cutter (PN SUM-900510) is made of powder-coated, billet aluminum. It works like a giant-sized tubing cutter in that it has a cutting wheel and a pair of opposing ball bearings. It is able to cut filters of up to 5 1/2 inches in diameter.

Note: Click on any of the images below for an expanded view:

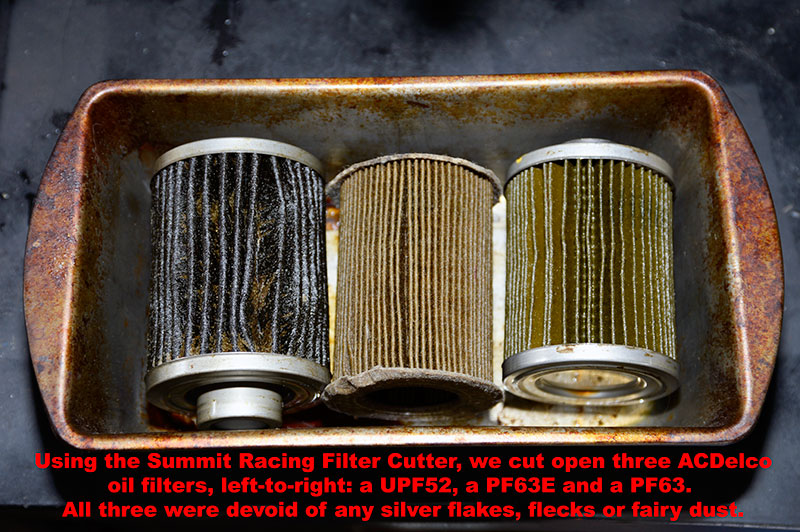

After you remove an oil filter, let it drain for several hours. Then, get out your Summit Filter Cutter. Its use is quite simple. You retract the cutter by turning the adjustment knob. Then, you set the filter on the two bearings such that you will cut the filter “can” just below the mounting flange. Next, tighten the cuter against the filter can. Hold the tool with one hand and use the other to rotate the filter. Turn the filter a couple of turns, then modestly tighten the adjuster and turn some more. You follow this turn-then-tighten procedure until the filter can is severed from the mounting flange. Toss the mounting flange and any rubber seals or rings you find at the top the filter in the recycling bin. Fish out the filter element, then recycle the filter can.

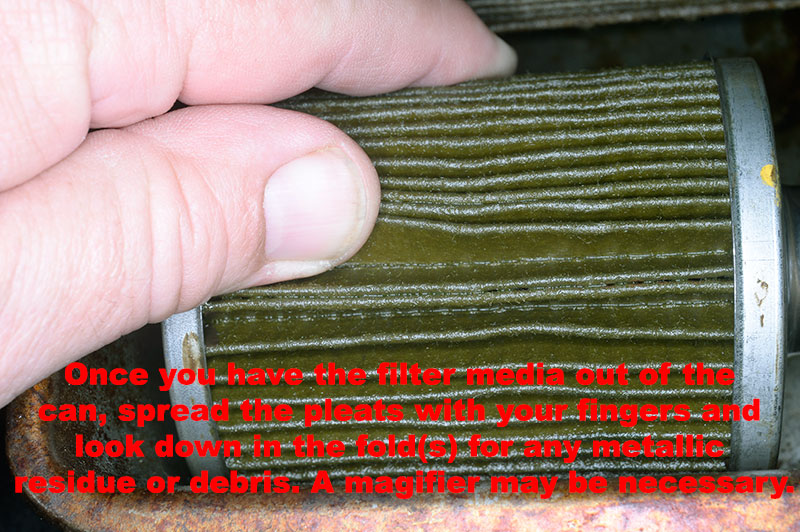

Oil flow in a spin-in filter is from the outer circumference of the filter, though the filter media, into the center of the filter and then upwards and out. Debris trapped by the filter will be visible in the pleats of the media. Use your fingers to spread the folds of filter media apart so you can see down into the pleats. Use a bright light to see into the pleats. What you don’t want to see is visible metallic debris–no metal flakes, no silver or bronze fairy dust. When you are done with your inspection, dispose of the filter element in the proper manner for hazardous material.

For more information on spectrographic oil analysis, see the Blackstone Labs web site. For more information on the Summit Racing Oil Filter Cutter click here.