ryanholt

New Member

I’ve had my 4BW for a little over a year and occasionally, I carry things in my trunk that I wouldn’t want stolen. I’ve seen a number of videos online where thieves have learned to break the rear door glass and flip down the rear seats of various cars in order to gain access to luggage and other items people keep in the trunk. Cadillacs suffer from this potential problem as there is no way to lock the rear seats in their up positions. Are you listening Cadillac? Additionally, the releases are located “conveniently” within arms reach if the rear windows are rolled down or broken out. The other time this comes into play is when you take your car for service or at the occasional valet. While the valet function of the car supposedly keep the trunk from opening, individuals with nefarious intent can simply lay down the rear seats and have full access to your valuables.

To solve this issue, I got on the web, Pinterest, Etsy, and Ebay as most problems like this have already been solved by someone else. The closest solution I could find was from an industrious individual who had 3D printed a shaped block that sits in the lever that you squeeze to unlock the rear seats that prevents your hand from being able to operate the lever, but only for Teslas. Droplock Rear Seat Lock for Model 3 - TESBROS Alas, no such solution appears to be available for the 4BW or its sister vehicles.

I have access to a 3D printer so I went to work trying to design a similar block for the 4BW but it was clear that an entirely different design would be necessary. Additionally, the Tesla solution seems to use a couple screws to create a compression style lock that would not work in the Cadillac. Without some kind of attachment device the block could easily be removed from blocking the lever and I wanted something that would require a thief to have some other tool with them to remove the block and gain access to the trunk.

I began with a set of calipers in the back seat of my 4BW and quickly got frustrated trying to do R&D in that space. A quick trip online and I was able to purchase the actual seat locking mechanism and trim piece at a cost I thought was reasonable for this project. The GM part numbers are 85594470 for the actual latch and 22821133 for the trim piece that goes on top of the latch. Most websites indicate that this particular latch is used in all 2023 variants of the CT4. The part number for the 2022 CT4 variants is different but looks exactly the same. I’d be very surprised if the shape is different for the CT4 models.

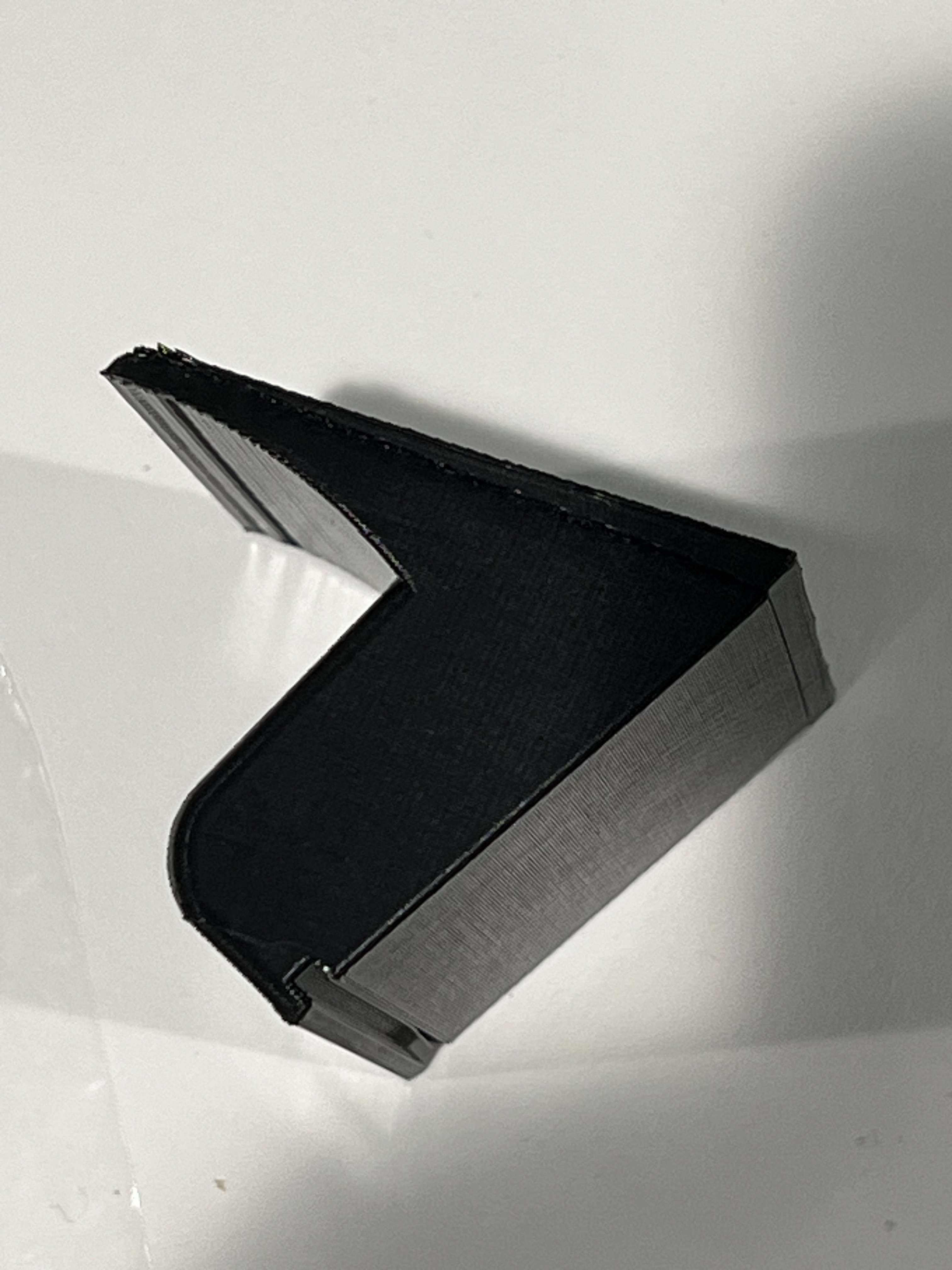

Eight iterations later, I found a shape that I liked that filled the hole where your hand would grab and would also serve as a cap for the action itself. Then I set about to solve the issue of the block being easily removable if you had a couple seconds to look at it.

I settled on using a net-cert that could be installed in the bottom of the lever and a machine screw with a button cap could be used to thread through the block into the lever itself. I redesigned the block to have a 5mm hole from the top surface to the bottom of the well where your fingers land when actuating the lever. I determined that 50mm long machine screw was necessary for the depth. I practiced installing the nut-cert in the extra mechanism that I purchased. I used the block as a drill guide with a 5mm drill bit to create a pilot hole and then used a 7mm drill to open the hole in the mechanism which is the size you need for 5mm nut-cert. To do this you need to use a screw driver or other metal rod to put the mechanism in the “locked” position so that the block wits in exactly the right place to drill the hole.

Obviously, you could use a 10-24 machine screw if you just don’t like using a metric version but you’d need to adjust your drill bits accordingly. Also, if you didn’t want to go to the extra trouble of installing a nut-cert, you could also use a course threaded screw of the appropriate length. I’d probably still drill a small pilot hole in the well of the lever, but any irregular hole you’d make using that kind of screw would be hidden at the bottom of the well and you’d be done a lot faster. To install the nut-cert you do have to do some yoga as you have to stabilize the seat in a ½ folded position and then work the nut-cert tool. It should be noted that you must be careful not to over compress the nut-cert as you are inserting it into the ABS plastic used to create the lever mechanism. I was able to practice on my extra mechanism and wasted two or three nut-certs first before I figured out how to not over compress them.

To solve this issue, I got on the web, Pinterest, Etsy, and Ebay as most problems like this have already been solved by someone else. The closest solution I could find was from an industrious individual who had 3D printed a shaped block that sits in the lever that you squeeze to unlock the rear seats that prevents your hand from being able to operate the lever, but only for Teslas. Droplock Rear Seat Lock for Model 3 - TESBROS Alas, no such solution appears to be available for the 4BW or its sister vehicles.

I have access to a 3D printer so I went to work trying to design a similar block for the 4BW but it was clear that an entirely different design would be necessary. Additionally, the Tesla solution seems to use a couple screws to create a compression style lock that would not work in the Cadillac. Without some kind of attachment device the block could easily be removed from blocking the lever and I wanted something that would require a thief to have some other tool with them to remove the block and gain access to the trunk.

I began with a set of calipers in the back seat of my 4BW and quickly got frustrated trying to do R&D in that space. A quick trip online and I was able to purchase the actual seat locking mechanism and trim piece at a cost I thought was reasonable for this project. The GM part numbers are 85594470 for the actual latch and 22821133 for the trim piece that goes on top of the latch. Most websites indicate that this particular latch is used in all 2023 variants of the CT4. The part number for the 2022 CT4 variants is different but looks exactly the same. I’d be very surprised if the shape is different for the CT4 models.

Eight iterations later, I found a shape that I liked that filled the hole where your hand would grab and would also serve as a cap for the action itself. Then I set about to solve the issue of the block being easily removable if you had a couple seconds to look at it.

I settled on using a net-cert that could be installed in the bottom of the lever and a machine screw with a button cap could be used to thread through the block into the lever itself. I redesigned the block to have a 5mm hole from the top surface to the bottom of the well where your fingers land when actuating the lever. I determined that 50mm long machine screw was necessary for the depth. I practiced installing the nut-cert in the extra mechanism that I purchased. I used the block as a drill guide with a 5mm drill bit to create a pilot hole and then used a 7mm drill to open the hole in the mechanism which is the size you need for 5mm nut-cert. To do this you need to use a screw driver or other metal rod to put the mechanism in the “locked” position so that the block wits in exactly the right place to drill the hole.

Obviously, you could use a 10-24 machine screw if you just don’t like using a metric version but you’d need to adjust your drill bits accordingly. Also, if you didn’t want to go to the extra trouble of installing a nut-cert, you could also use a course threaded screw of the appropriate length. I’d probably still drill a small pilot hole in the well of the lever, but any irregular hole you’d make using that kind of screw would be hidden at the bottom of the well and you’d be done a lot faster. To install the nut-cert you do have to do some yoga as you have to stabilize the seat in a ½ folded position and then work the nut-cert tool. It should be noted that you must be careful not to over compress the nut-cert as you are inserting it into the ABS plastic used to create the lever mechanism. I was able to practice on my extra mechanism and wasted two or three nut-certs first before I figured out how to not over compress them.